Background

The European chemical industry faces multiple pressures for emissions reduction, disadvantage in feedstock cost to other regions, and partially stagnating markets.

CO and CO2 represent alternative, abundant and valuable sources of carbon which can be a suitable raw material. Their utilization has the potential to contribute significantly to reducing greenhouse gas emissions and thereby unwanted climate change effects. In addition, the utilisation of CO and CO2 as a feedstock by the European process industry to produce materials and chemicals can become a key solution to reduce the EU dependence on imports of fossil resources providing a secure supply of carbon feedstock while contributing to the EU emission reductions commitments.

Acknowledging the EU fossil resources dependency and climate change challenge, in 2015, the EU launched the SPIRE-08-2017, “Carbon dioxide utilisation to produce added value chemicals” call for action, as part of the Horizon 2020 programme. The aim of the call has been to support innovative chemical processes to produce added value chemicals from CO and CO2 and demonstrate the technical and economic feasibility in an industrially relevant environment.

Carbon4PUR research and innovation project addresses the scope of this topic.

Concept

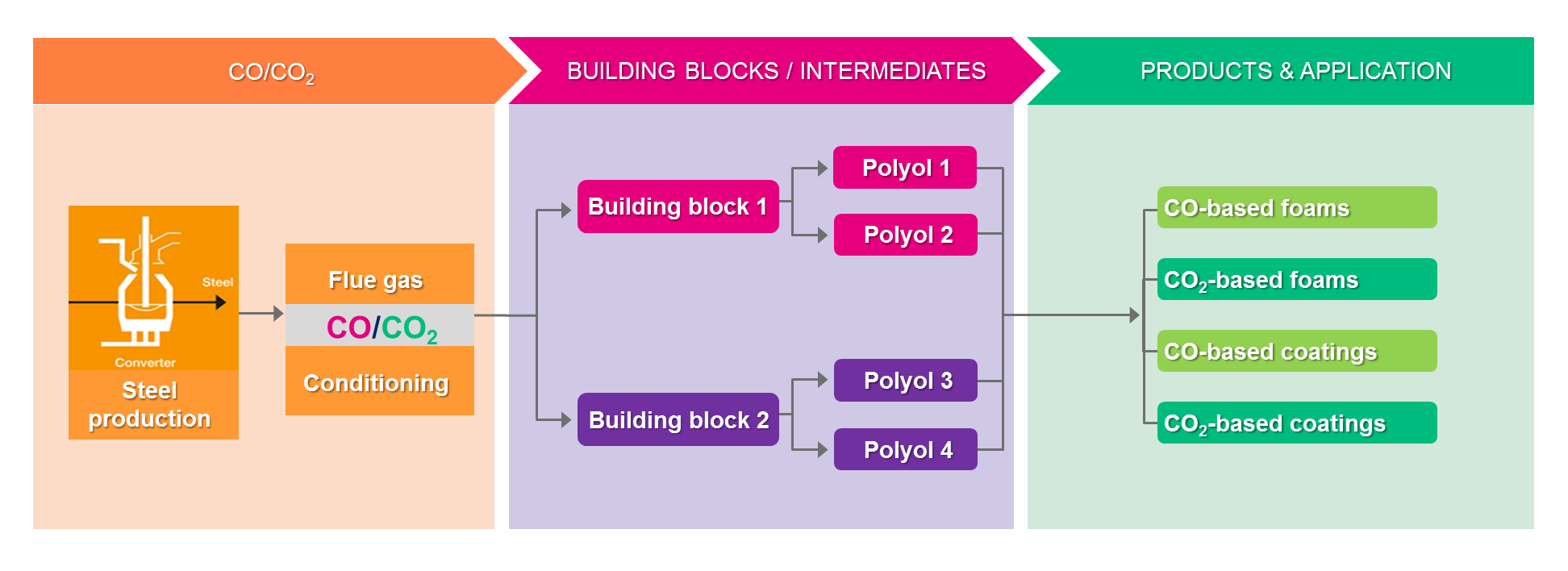

The industrially driven, multidisciplinary Carbon4PUR consortium will develop and demonstrate a novel process based on direct chemical steel mill gas mixture conversion, avoiding expensive physical separation, thus substantially reducing the carbon footprint and also contributing to high monetary savings. The consortium and the development are organized along the full value chain starting with the provision and conditioning of industrial emissions from a steel to a chemical company fully in line with the concept of industrial symbiosis, going through the transformation into chemical building blocks and from the CO and CO2 based polymer intermediates, finally arriving at the implementation into rigid foams and coatings.

Objectives

The general objective of the Carbon4PUR project is to develop and demonstrate (TRL4-6) a new flexible technology for the production of value-added chemicals, polyester polyols, of carbon derived from steel mill gas. Specially, the consortium will:

- Reduce carbon footprint of polyurethane intermediates compared to today’s polyurethane products manufactured from crude oil due to the re-utilisation of anthropogenic CO and CO2.

- Provide – first time from waste CO – higher value novel polyols for the production of new, sustainable polyurethane applications (rigid foam and coatings) as an example of high value polymers, matching market needs and requirements.

- Implement a direct conversion of carbon from the steel mill gas mixture to building blocks for the production of polyol intermediates.

- Condition industrial steel mill gas by avoiding expensive “traditional” purification and conditioning methods.

- Prepare Industrial Symbiosis between consortium partners in the Port Maritime de Fos (France).

- Demonstrate the economic and social feasibility of the new technology.

- Exploit and transfer project results to key stakeholders and additional EU industries.

Benefits

Carbon4PUR is highly ambitious with respect to scientific knowledge, industrial advancement, and environmental and social impacts.

- Carbon4PUR is developing knowledge and will demonstrate an innovative technology for the production of value added chemicals derived from steel mill gas streams.

- Carbon4PUR will help the EU process industry to reduce its dependency on imports of petrochemicals resources and to provide a secure supply of carbon feedstock.

- Carbon4PUR will contribute significantly to the reduction of the GHG emissions.

- Carbon4PUR will increase the industrial competitiveness from the adoption of a novel production process of added-value chemicals.

- Carbon4PUR will contribute to the creation of new employment and job security in the EU industry.

- Carbon4PUR is contributing to Industrial Symbiosis [1].

[1] Industrial Symbiosis is referred to the synergistic exchange of waste, by-products, water and energy between individual companies. The contribution of Industrial Symbiosis to EU sustainable economy and resource efficiency is recognized in The Roadmap to a Resource Efficient Europe (COM(2011)571), which points out that improving the reuse of raw materials through greater ‘Industrial Symbiosis’ could save EUR 1.4 billion a year across the EU and generate EUR 1.6 billion in sales.